Precision Machining Excellence for Brittle Materials

Achieving precise dimensions and surface finishes in brittle materials requires specialized expertise. Vitreous Forge delivers consistent tolerances down to ±0.001" and surface finishes as fine as Ra 0.1 for the most demanding applications in aerospace, medical devices, semiconductors, and optics.

- Dimensional Accuracy: ±0.001"

- Surface Finishes: Ra 0.1

- Material Compatibility: Advanced Ceramics, Technical Glass, Composites

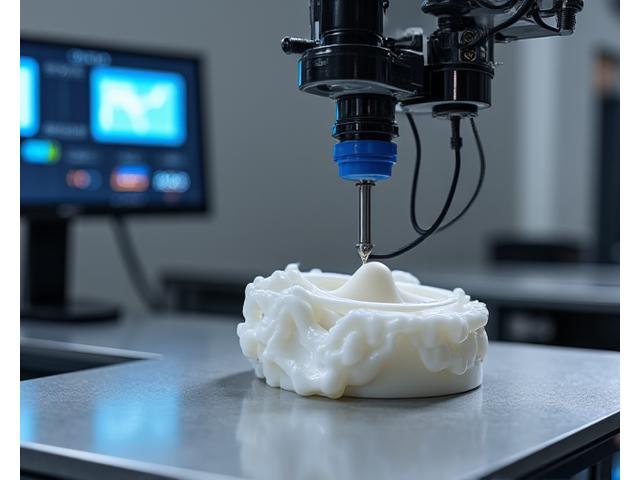

Advanced Manufacturing Technology

5-Axis CNC Precision

Our state-of-the-art 5-axis CNC machining centers are specifically configured to navigate the unique challenges of brittle materials, delivering unparalleled precision and efficiency for complex geometries.

Ultrasonic Machining

Unlock design possibilities with ultrasonic machining, perfect for creating precise internal features, high aspect ratio holes, and delicate structures in advanced ceramics and glass without micro-cracking.

Laser Processing

Utilize focused laser energy for precise cutting, drilling, and surface texturing. Our laser processing capabilities offer fine detail and minimal heat-affected zones, critical for sensitive materials.

Automated Inspection

Ensure every component meets your exact specifications with our integrated automated inspection systems, including advanced Coordinate Measuring Machines (CMMs) for comprehensive dimensional verification.

Cleanroom Machining

For applications requiring the utmost purity and particulate control, our ISO-certified cleanroom facilities provide an aseptic environment for machining medical, semiconductor, and optical components.

Our Proven Machining Process

Design Review & Analysis

Collaborative review ensuring designs are optimized for manufacturability, material compatibility, and cost-efficiency, mitigating risks before production.

Tooling & Parameter Optimization

Expert selection of specialized tooling and precise optimization of cutting parameters to minimize material stress and achieve superior surface integrity.

Multi-Stage Machining & QC

Rigorous multi-stage machining processes combined with integrated quality checkpoints ensure consistency and adherence to specifications throughout production.

Final Inspection & Documentation

Comprehensive final inspection processes ensure every component surpasses quality standards, complete with detailed documentation and traceability reports.

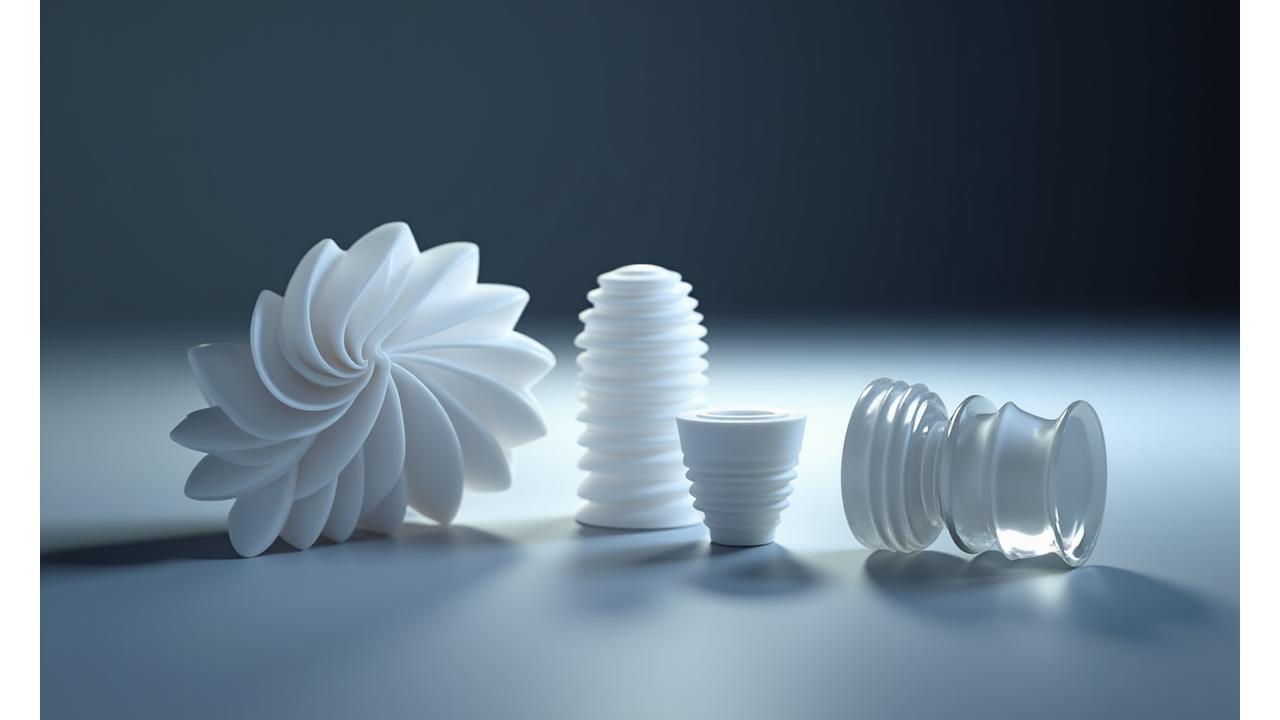

Complex Geometries We Machine

Micro-Features & Thin-Walled Structures

Fabrication of components with features sometimes smaller than a human hair and walls as thin as 0.1mm, maintaining structural integrity in technical ceramics.

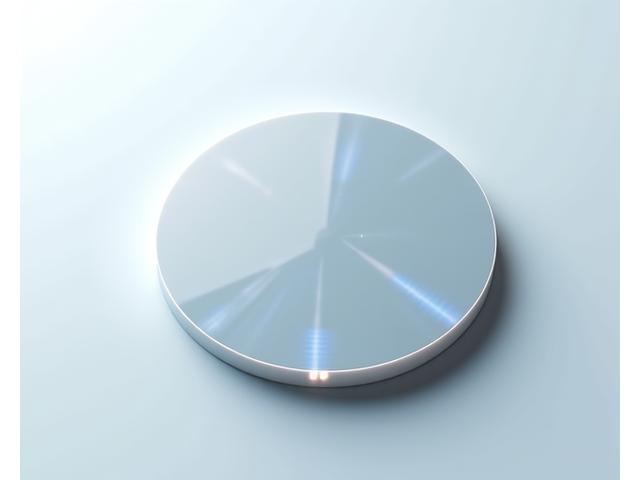

Optical Components with Precision Surfaces

Manufacturing optical elements from fused silica and other technical glasses to achieve ultra-smooth surfaces and precise geometrical conformity critical for imaging and lensing applications.

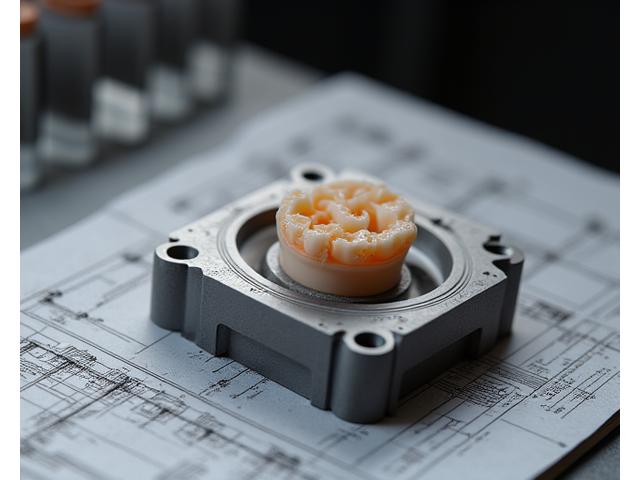

Medical Implant Components

Producing highly detailed, dimensionally accurate components from biocompatible ceramics like zirconia and alumina for critical medical and dental implant applications.

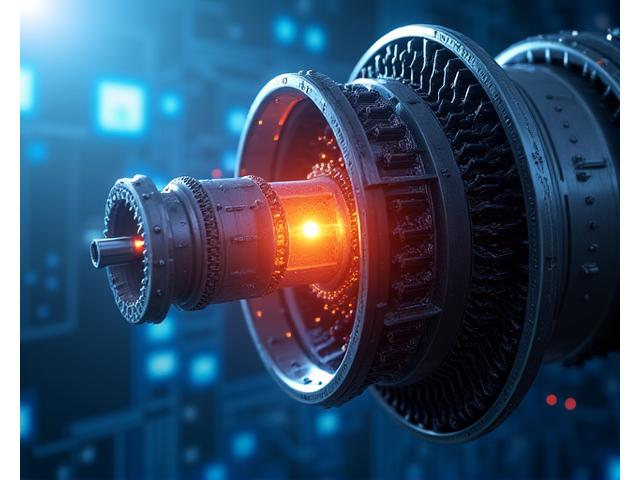

Aerospace Components with Extreme Tolerances

Machining high-performance ceramic aerospace components, including turbine parts, thermal shrouds, and sensor housings, designed to withstand extreme environments with uncompromising precision.

Custom Fixtures & Tooling

Beyond direct product componentry, we engineer and precision machine custom fixtures, tooling, and prototypes crucial for research, development, and specialized production processes.

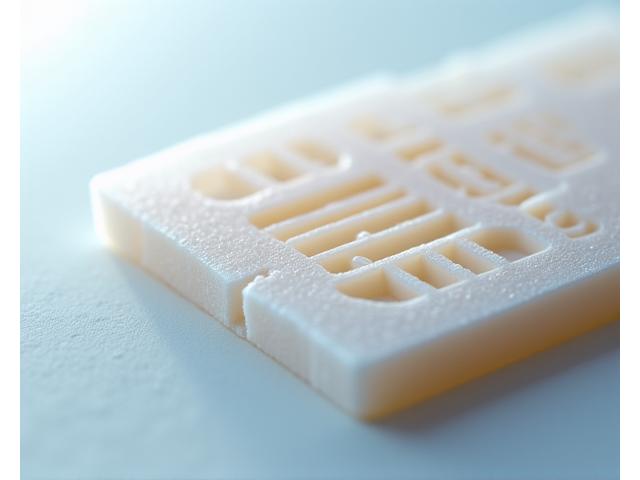

Semiconductor Components

Precision machining of ceramic and glass components for semiconductor manufacturing, including wafer chucks, process tooling, and structural parts that demand extreme flatness and purity.

Rigorous Quality Control

At Vitreous Forge, quality isn't just a checkpoint; it's integrated into every phase of our precision machining process. Our uncompromising standards ensure that every component we deliver performs flawlessly in its mission-critical application.

- In-Process Monitoring: Real-time feedback loops to maintain tight control over every cut and finish.

- Advanced Metrology: Coordinate Measuring Machines (CMMs) and optical profilometers for sub-micron dimensional verification.

- Statistical Process Control (SPC): Proactive quality management to guarantee consistency and minimize variation across production runs.

- Complete Traceability: Comprehensive documentation providing full material and process traceability for every component.

Specialized Material Knowledge

Our expertise extends beyond machining; we possess deep scientific understanding of the diverse properties of advanced ceramics and technical glasses, ensuring optimal material selection and processing for your specific needs.

Alumina & Zirconia

Exceptional wear resistance and high strength for industrial and biomedical applications.

Silicon Carbide & Nitride

Superior thermal stability and chemical inertness for extreme high-temperature environments.

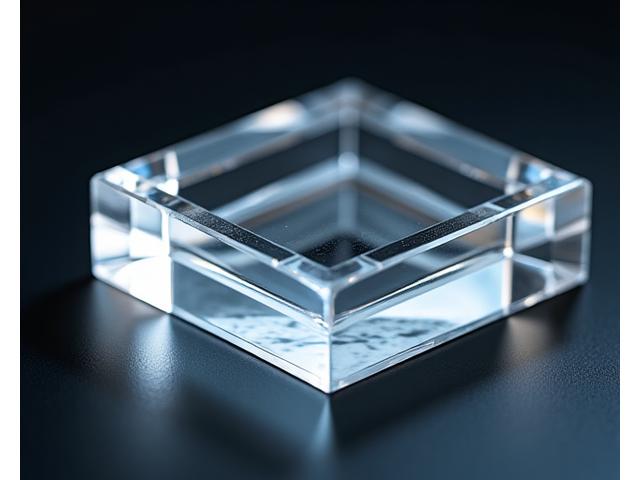

Borosilicate & Fused Silica

Unmatched optical clarity and thermal shock resistance for advanced photonics.

Custom Material Guidance

Leverage our material scientists to select or formulate the ideal ceramic or glass for your application's unique demands.

Get Your Precision Machining Quote

Ready to transform your complex designs into high-performance components? Submit your requirements below for a rapid and accurate quote. Our engineering team is ready to consult on your most challenging projects.

Prefer to discuss your project directly? Call us at (954) 776-8901 or email [email protected].