Aerospace Turbine Blade Thermal Shock

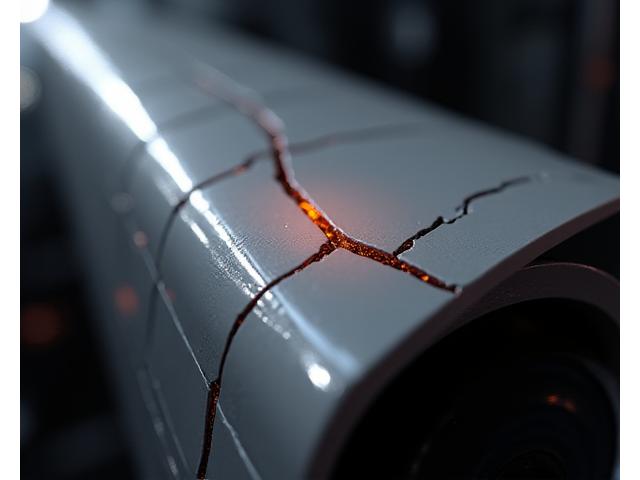

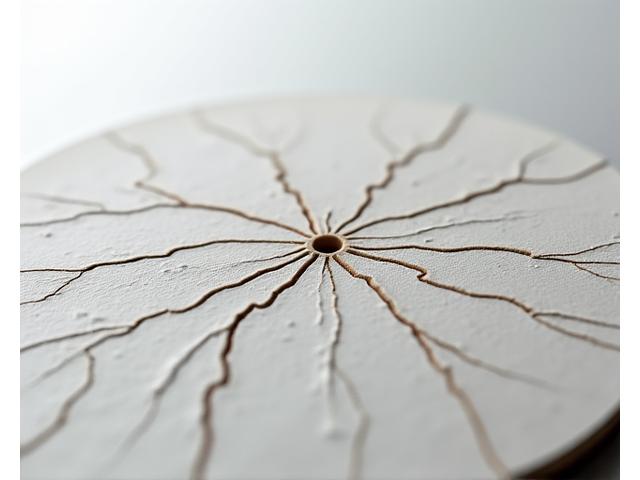

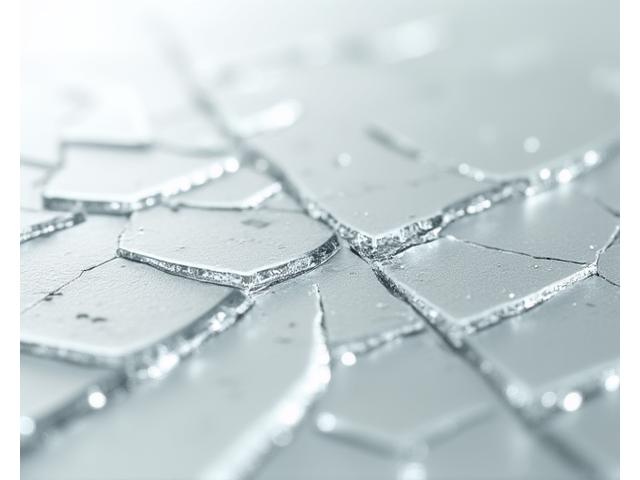

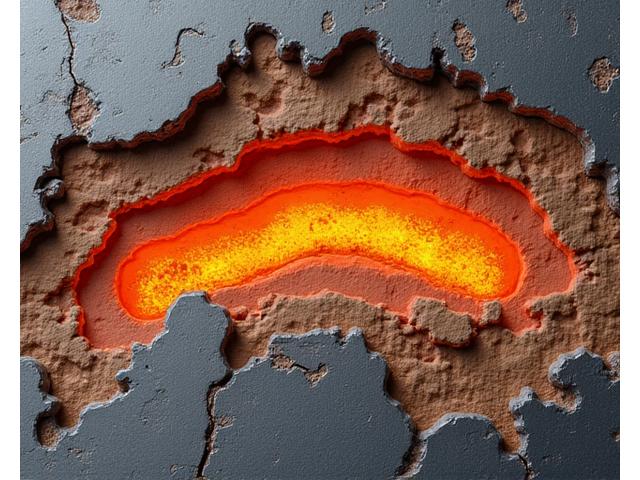

A ceramic turbine blade for a hypersonic engine experienced premature cracking. Our analysis pinpointed localized thermal gradients exceeding the material's critical thermal shock parameter. We recommended design modifications and a new ceramic matrix composite, extending operational life by 200%.