Unlock Breakthrough Aerospace Performance with Ceramic Matrix Composites

Vitreous Forge engineers ceramic matrix composites (CMCs) that redefine the limits of aerospace materials. Operating at temperatures 500°F higher than traditional superalloys, our CMCs reduce component weight by up to 50%, enabling revolutionary efficiency and performance for next-generation aircraft.

- Extreme Temperature Resistance exceeding 2500°F

- Significant Weight Reduction for Enhanced Fuel Efficiency

- Proven Performance in Mission-Critical Aerospace Applications

Advantages Over Traditional Materials

Superior Temperature Capability

Operate reliably 500-1000°F higher than conventional superalloys, enabling more efficient engine designs and enhanced performance margins.

Significant Weight Reduction

Achieve 40-60% weight reduction compared to metallic alternatives, directly translating to improved fuel efficiency and payload capacity.

Exceptional Thermal Shock Resistance

Maintain structural integrity through rapid temperature fluctuations, crucial for demanding aerospace flight cycles and re-entry applications.

Enhanced Oxidation Resistance

Provide long-term stability and extended service life in aggressive, high-temperature oxidizing environments typical of jet engines and hypersonic regimes.

Critical Aerospace Applications

- Turbine Engine Combustors & Nozzles: For improved fuel efficiency and reduced emissions at higher operating temperatures.

- Hypersonic Vehicle Thermal Protection: Leading edge components enduring extreme heat for re-entry and high-speed flight.

- Exhaust System Components: Reducing weight and improving durability under severe thermal cycling.

- Structural Panels: For high-temperature zones within aircraft and spacecraft, offering superior strength-to-weight ratios.

- Brake Discs & Thermal Management: Dissipating heat efficiently in critical braking and cooling systems.

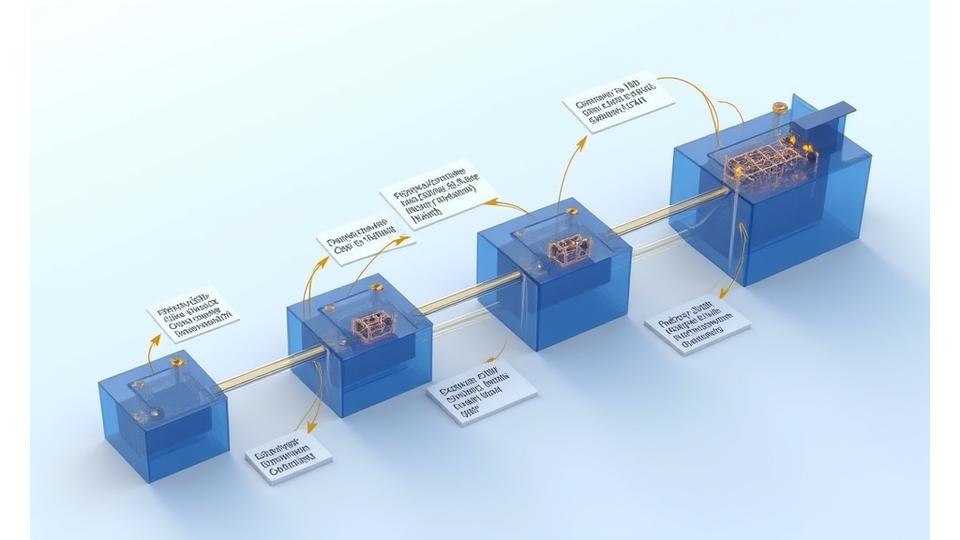

Advanced CMC Manufacturing Capabilities

Precision Processes for Optimal Performance

Vitreous Forge utilizes a suite of cutting-edge manufacturing processes to produce CMCs tailored precisely to your application's demands. Our expertise ensures both complex geometries and superior material properties.

- Polymer Infiltration and Pyrolysis (PIP): Ideal for complex geometries and cost-effective prototyping.

- Chemical Vapor Infiltration (CVI): For high-density, high-purity composites with exceptional environmental resistance.

- Slurry Infiltration Processing: Delivering cost-effective production for certain fiber architectures.

- Custom Fiber Preform Manufacturing: Tailored weaving and braiding techniques for optimized structural performance.

- Net-Shape and Near-Net-Shape Manufacturing: Minimizing post-processing and material waste.

Proven Performance in Aerospace Environments

Our CMCs undergo rigorous testing and validation to ensure they meet and exceed the demanding requirements of aerospace applications. Trust in data-driven reliability.

- High-Temperature Mechanical Property Retention: Demonstrating strength and stiffness at operational extremes.

- Thermal Cycling Test Results: Verifying durability under rapid and repeated temperature changes.

- Oxidation Resistance Testing: In simulated and actual high-temperature, oxidative environments.

- Fatigue Life Data: Under realistic aerospace loading conditions for long-term reliability.

- Flight Test Validation: Real-world performance monitoring and verification.

Aerospace Quality & Certification

Vitreous Forge maintains an unwavering commitment to the highest quality standards, ensuring every CMC component meets the stringent requirements of the aerospace industry.

AS9100 Certified

Our quality management system is fully certified to AS9100 standards, governing all aspects of design, development, and manufacturing.

NADCAP Accreditation

Accredited for specialized processes crucial to advanced materials manufacturing, ensuring consistent excellence and reliability.

Material Qualification Support

Comprehensive support for material qualification processes, partnering with aerospace OEMs to ensure seamless integration and approval.

Partner with Vitreous Forge for Your Next Aerospace Innovation

Ready to elevate your aerospace designs with advanced ceramic matrix composites? Vitreous Forge offers collaborative development programs, expert technical consultation, and scalable manufacturing solutions to bring your vision to life.