Revolutionary 3D Printed Ceramic Solutions

At Vitreous Forge, we unlock unparalleled design freedom with advanced 3D printed ceramics, enabling complex internal structures, rapid prototyping, and custom geometries previously deemed impossible with conventional manufacturing.

- Unprecedented design freedom for intricate ceramic components.

- Create complex geometries that defy traditional ceramic processing limitations.

- Accelerate product development cycles with rapid prototyping capabilities.

- Deliver custom components with integrated functionality and superior performance.

Advanced Ceramic 3D Printing Technologies

Our diverse suite of ceramic additive manufacturing processes ensures optimal solutions for precision, scale, and material versatility.

Stereolithography (SLA)

Achieve ultra-high resolution ceramic parts with exceptional surface finish, ideal for intricate prototypes and precision components.

Binder Jetting

Efficiently produce large parts and high production volumes with diverse ceramic compositions, reducing costs and lead times.

Direct Ink Writing

Utilize custom paste formulations to create unique ceramic structures with tailored material properties, perfect for functional research.

Selective Laser Sintering (SLS)

Fabricate highly dense and robust ceramic structures suitable for demanding applications requiring superior mechanical strength.

Multi-Material Printing

Innovate with functionally graded components, combining different ceramic compositions to achieve diverse properties within a single part.

Unlocking Superior Performance Through Design

3D printed ceramics transcend traditional manufacturing limits, offering design flexibility that translates directly into enhanced performance and efficiency.

-

Internal Channels & Passages

Precisely engineered internal cooling and fluidic channels for superior thermal management and flow optimization in critical applications.

-

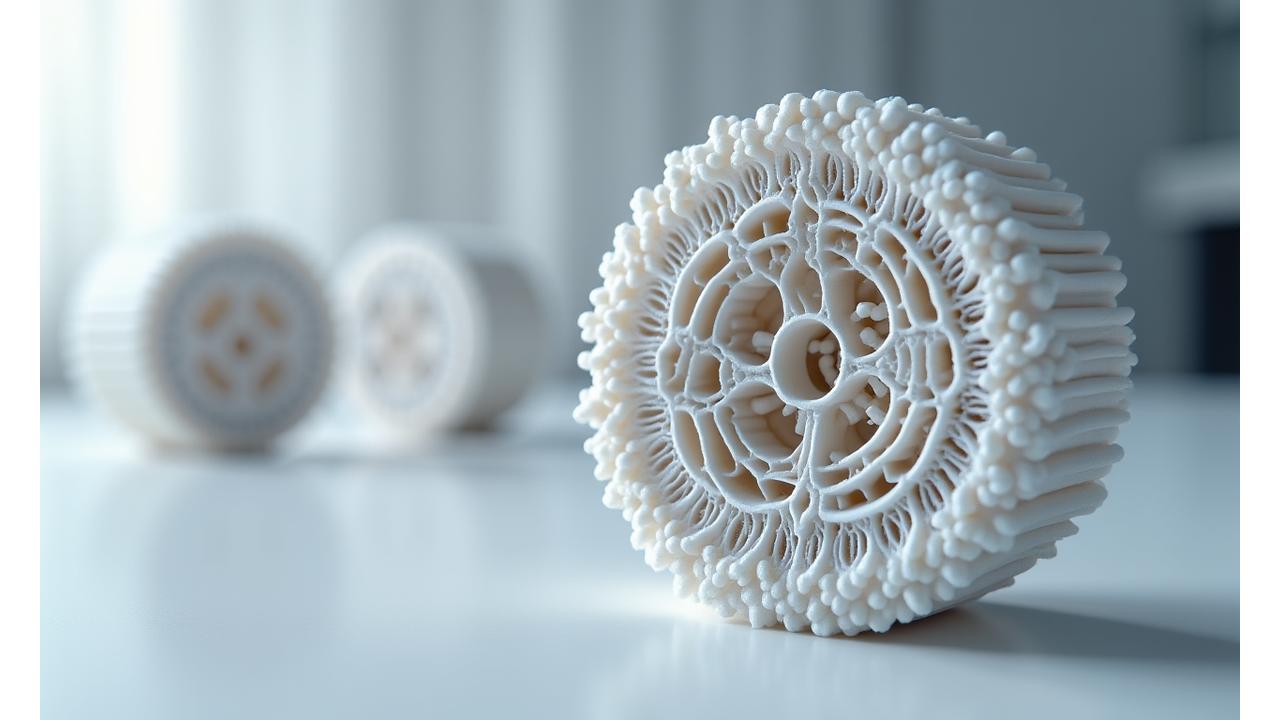

Lattice Structures

Fabricate lightweight, high-strength components with optimized strength-to-weight ratios for aerospace and industrial demanding environments.

-

Integrated Features

Consolidate multiple parts into a single, complex ceramic component, eliminating assembly requirements and reducing potential failure points.

-

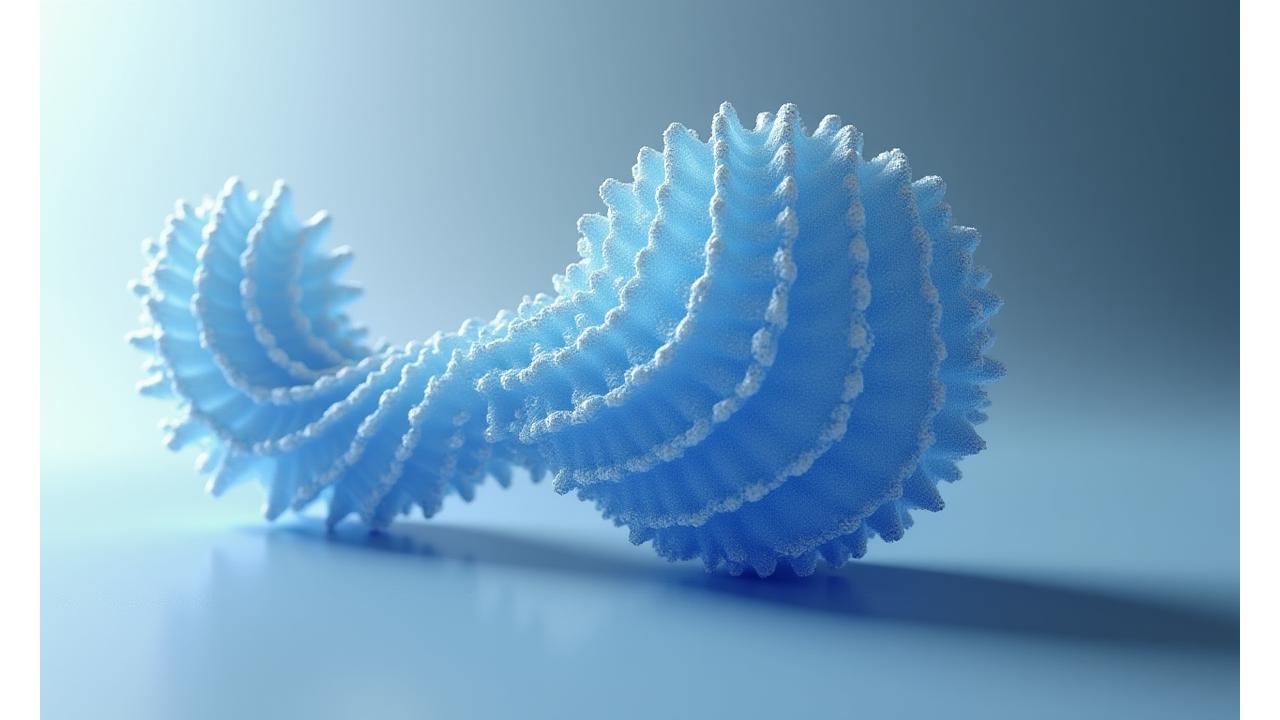

Biomimetic Inspirations

Leverage the efficiency of natural designs to create ceramic structures with advanced functionality and optimized performance characteristics.

-

Topology Optimization

Maximize performance efficiency by algorithmically designing ceramic components for optimal material distribution and structural integrity.

Innovative Applications Across Diverse Industries

Our 3D printed ceramic solutions are empowering breakthroughs in mission-critical applications where traditional materials fall short.

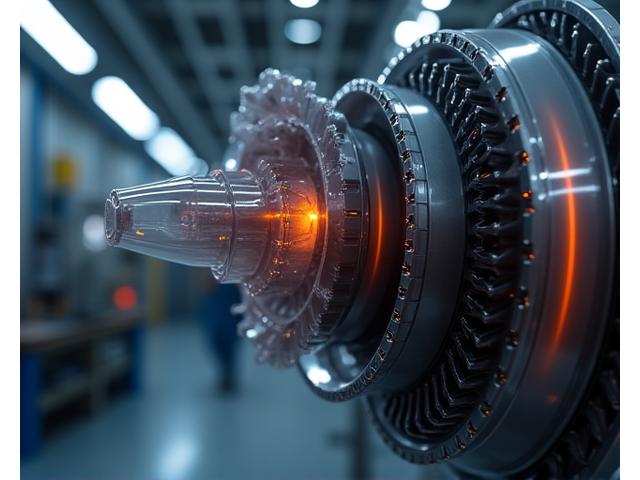

Aerospace

Complex turbine components with intricate internal cooling channels for enhanced efficiency and durability in extreme temperatures.

Medical

Custom implants and surgical guides, precisely tailored to patient anatomy for improved outcomes and expedited recovery.

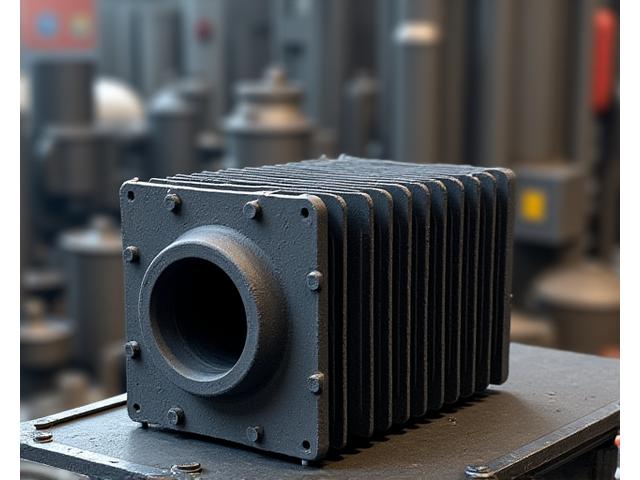

Industrial

Advanced heat exchangers with optimized flow geometries for superior thermal efficiency and extended service life in harsh industrial environments.

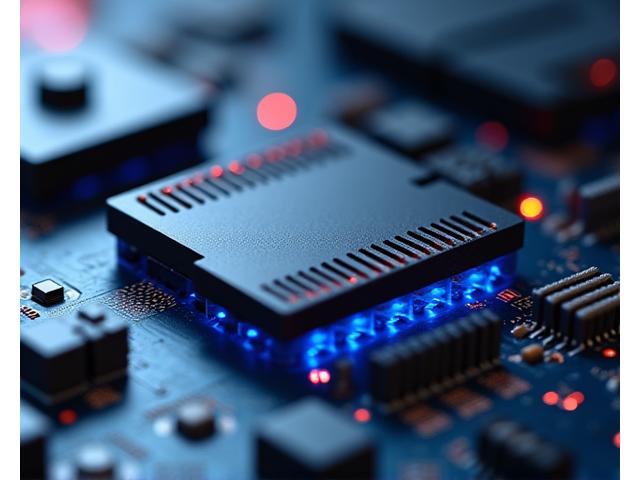

Electronics

Custom housings and substrates with integrated thermal dissipation channels, ensuring optimal performance and longevity for sensitive electronic components.

Comprehensive Ceramic Material Portfolio

Vitreous Forge leverages a broad spectrum of advanced ceramic materials, each selected and optimized for specific additive manufacturing processes and application requirements.

Alumina (Aluminum Oxide Al2O3)

Exceptional wear resistance, high-temperature stability, and excellent electrical insulation properties for diverse industrial uses.

Zirconia (Zirconium Dioxide ZrO2)

High mechanical strength, fracture toughness, and biocompatibility, ideal for biomedical and structural applications.

Silicon Carbide (SiC)

Superior high-temperature resistance, excellent thermal conductivity, and chemical inertness for extreme environment components.

Hydroxyapatite (HAp)

Biocompatible and osteoconductive, utilized primarily for biomedical implants and bone replacement applications due to its strong affinity with biological systems.

Custom Formulations

Developed in-house, tailored to specific customer thermal, mechanical, and electrical requirements, ensuring optimal performance for unique challenges.

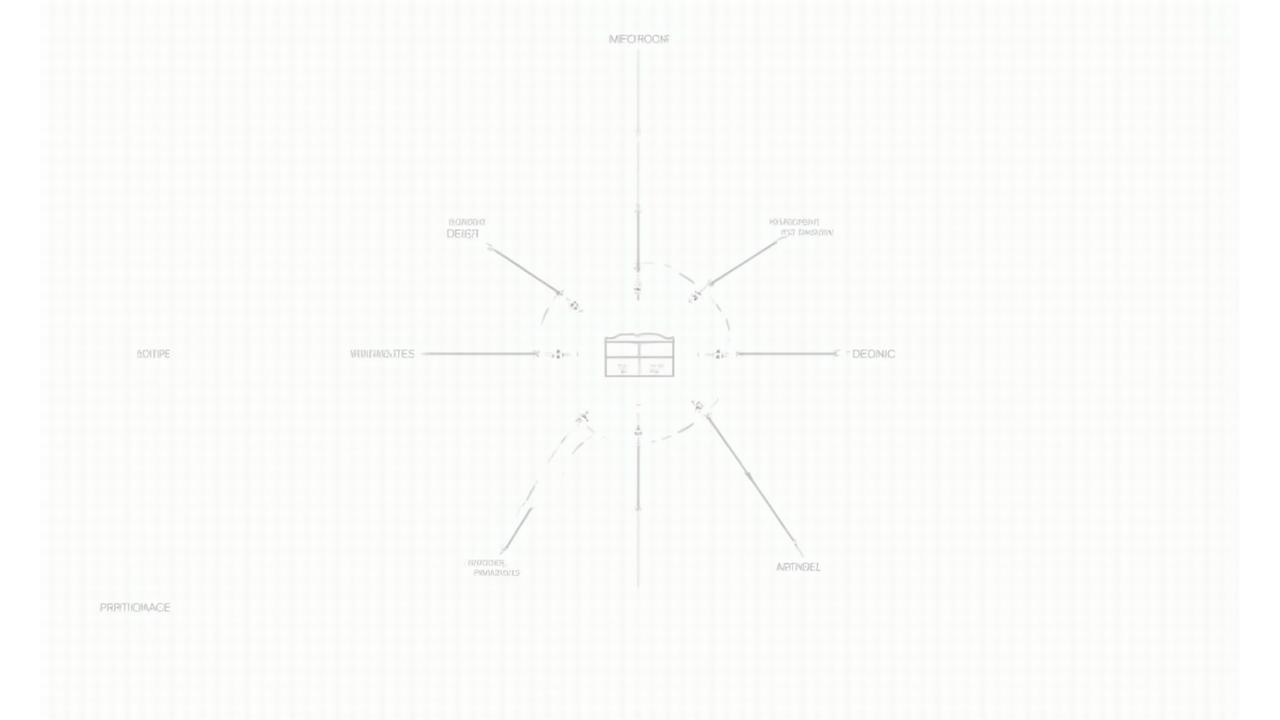

Accelerated Development Process for Rapid Innovation

Our streamlined development approach rapidly moves your ceramic designs from concept to functional prototype and production, significantly reducing time-to-market.

Digital Design Optimization

Precise design for additive manufacturing (DfAM) ensuring printability and optimal performance characteristics.

Rapid Printing & Post-Processing

Quick turnaround times for ceramic prototypes through optimized printing and efficient post-manufacturing steps.

Iterative Refinement

Continuous design iteration and testing feedback cycle for rapid optimization and functional validation.

Start Your Advanced Ceramic 3D Printing Project

Ready to transform your complex designs into high-performance ceramic realities? Vitreous Forge is your partner in innovation.

- Expert design consultation for manufacturability and performance.

- Secure CAD file upload and comprehensive printability analysis.

- Tailored material selection guidance based on your specific application.

- Scalable production solutions from rapid prototypes to high-volume manufacturing.